|

|

|

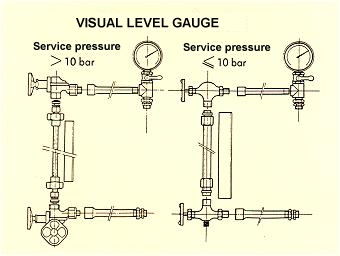

In conformity with the beside drawing,

|

|

|

Alignment of the two valves, and the glass tube must be perfect.

|

|

|

The tank, on which this equipment is mounted is ready to be used, but pumps stopped. It contains a certain water and air quantity at the static pressure.

|

|

|

At a given pressure, always corresponds a given water level in the vessel. At regular intervals, check for leaks. If the stabilised water level is above the mark on the glass tube, open the bleed cock on the bottom part of the tank. If you obtain water, the bladder is pierced, if no water, there is leak of air on the tank or the level gauge - you have to find and solve it. WHEN THE VESSEL IS OPERATING, THE LEVEL GAUGE HAS TO BE PERMANENTLY EMPTY ( UP AND DOWN VALVES CLOSED ) ! |

|

|

PLEASE

CONSULT US, OUR STUDIES ARE FREE OF CHARGE

|

|