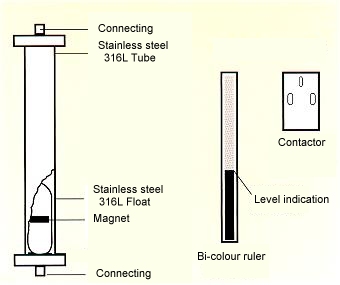

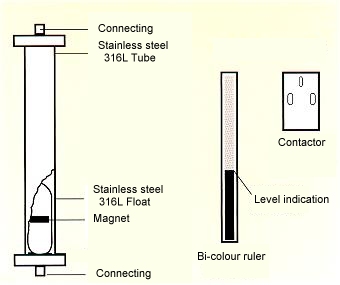

- A tube made of

STAINLESS STEEL 316L non-magnetic

-

A

Float made of STAINLESS STEEL 316L non-magnetic, with a magnet ( ballasted

in function of the fluid density contained in the vessel )

-

A ruler fitted with bi-colour rotating magnetics flaps.

-

Contactors

(Option)

|

-

Connect

the upper part of the magnetic level gauge through the «gas» outlet

of the tank.

-

Connect

the bottom part of the magnetic level gauge through the «Water» outlet

of the tank. With this instrument, we reproduce the principle of communicating

vessels.

|

|

|

|

|

-

On

this level gauge, we can place as much contactors as the length of

the tuber allows it.

-

As

a general rule, two contactors are used :

security «lack of air» security «lack of water»

-

In

normal functioning, mark the mini and maxi level.

- Install the contactor

« security lack of water » below mini level,

-

Install

the contactor « security lack of air » above maxi level.

-

In

case of dysfunctioning « security lack of water » the float will pass

before the contactor « mini level » and will cause over falling of

the contactor.

-

In

case of dysfunctioning « security lack of air » the float will pass

before the contactor « maxi level » and will cause over falling of

the contactor.

Then

we only need to record these two informations to get tele-alarms

and allow manual maintenance interventions.

- It is also possible,

with two more contactors, to stop completely the installation in case

of level too high or too low.

|

|

|

PLEASE

CONSULT US, OUR STUDIES ARE FREE OF CHARGE

|