|

|

|

LE RESERVOIR MASSAL - Société Anonyme au Capital de 6.250.000F |

| CHEMIN DES SEPT FONTS - BP 117 - 34302 AGDE CEDEX 02 - FRANCE - TEL. 33 (0)4 67 94 79 11 - FAX. 33 (0)4 67 21 06 89 |

|

E-mail : MASSAL@wanadoo.fr Web : http://www.massal.com |

|

R.C.S. Béziers B 345 355 622 000 19 - NAF 282 A - N° TVA CEE FR 81 345 355 622 |

|

SIRET 345 355 622 000 19 - A P E : 2408 |

|

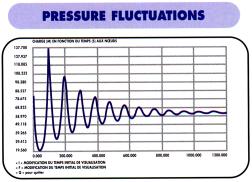

| Pressurized systems subjected to Pump Stoppages, Valves Closures, etc ..., may be suffering from surge phenomenna during transients due to changes of flow velocities. |

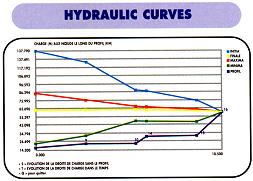

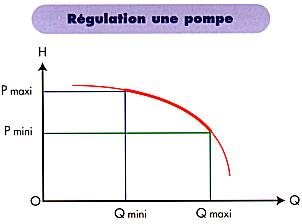

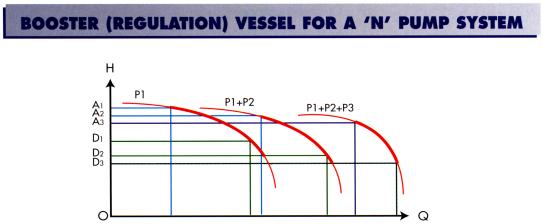

| It is an hydraulic phenomenum caused by velocity changes of the fluid being transported within the pipeline. It is characterised by a noise, but above all, by pressure changes which range from total vaccum ( cavitation ) to important over-pressures. They may seriously damage the system and its components. If surge is detected through a surge analysis, it is necessary to cancel or limit this phenomenum by installing an adequate protection device. There are many of such devices and the choice is dictated by the individual conditions of each system. |

|

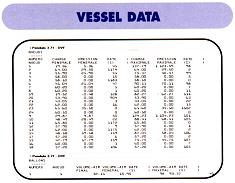

LE RESERVOIR MASSAL has acquired a reputable software with which it carries out simulations for itd Customers to define if there is a problem or no, and when necessary to recommend the most economical cure ( protection ) for the said problem. DATA TO BE SUPPLIED :

|